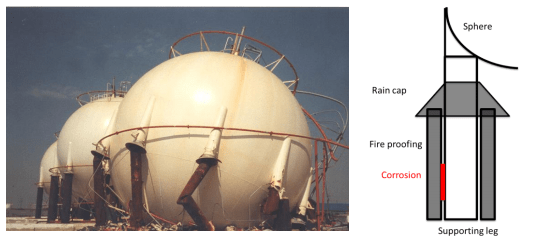

The annular plate region of above ground storage tanks is critical to its integrity, since it has the highest mechanical stress. At the same time, sagging of the tank can open it seal and expose the underside to air and water to start corrosion. If left unchecked, the tank may catastrophically fail, releasing its content in a short time.

Challenges in Storage Tank Annular Plate :

- Annular plate region is prone to accelerated corrosion due to the additional stresses caused by the weight of the tank wall and higher possibility of water entrapment under the annular plate. Thus conventional inspection techniques fall short in capturing desired data.

- Repairs in this region demand replacement of the entire annular plate and this leads to long shutdown of the tank, and often lead to failures without prior indications.

- Shutdown for carrying an inspection leads to time loss in emptying & refilling of tank and considerable amount of revenue losses to asset owners.

So how are we to inspect storage tank annular plate without a shut down?

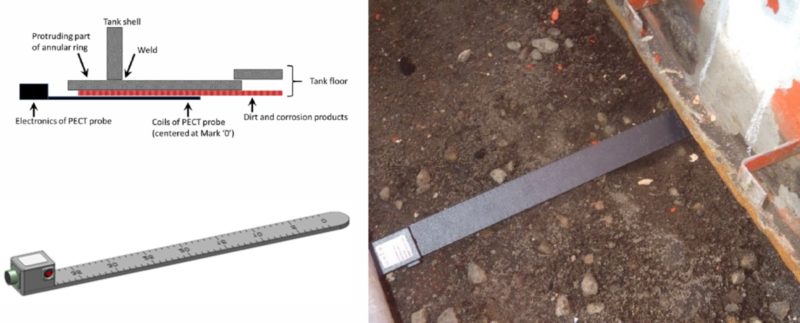

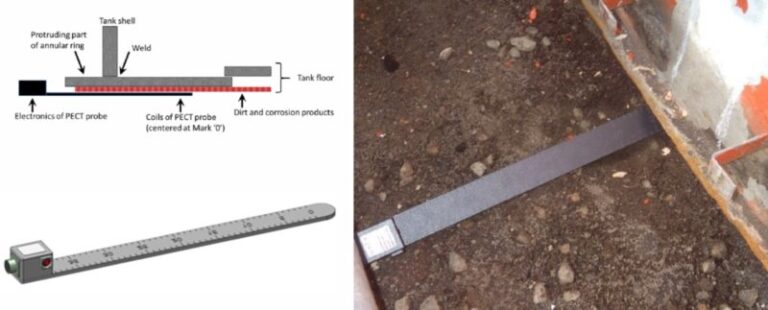

A flat PECT probe is inserted underneath the tank floor for in-service inspection. Such inspection is of great value, as it can help to extend the intervals between out-of-service inspection.

The graph represents an example result of an annular ring inspection, showing severe wall loss close to the tank shell. The corroded area extends over a length of about 80 mm in this case.

Standards guiding PEC Inspection :

ISO 20669