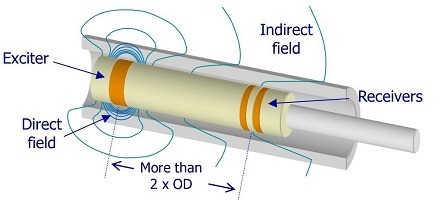

The Remote Field Technique is generally used to evaluate the condition of ferromagnetic tubes such as those found in process heat exchangers, boilers, and feedwater heaters. The most common material examined being carbon steel. The Remote Field Technique (RFT) should not be confused with other electromagnetic techniques such as eddy current, used to examine nonferrous materials. The RFT may be utilized to examine nickel, ferritic stainless and other tubing made of ferritic materials. Unlike eddy current, the RFT operates at lower frequencies, in the 50 to 500 Hz range for carbon steel. For inspection, an RFT probe, which has an exciter coil and two or more detector coils, is inserted into the tube. An A.C. magnetic field generated at the exciter coil transits out through the tube wall travels along the tube and passes back through the tube wall at a distance of more than two tube diameters. The tube wall thickness is directly related to the travel time or the phase of the A.C. magnetic field. Therefore, measurements of wall loss can be obtained using phase measurements.