Tube inspection is a vital tool for the refining and petrochemical industries. Heat exchangers and condensers are designed to sustain 100% separation between the products in the tube (tube side) and the products in the vessel (shell side). A leaking tube can not only cause a significant impact to production, it can also cause major environmental issues and the potential for loss of life. Heat exchanger tubes are typically small in diameter and numerous, some bundles containing as few as five tubes while others as many as 50,000. Tubing can be straight, curved or feature a twisted geometry, and typically require specific probes to inspect from the inside of the tube.

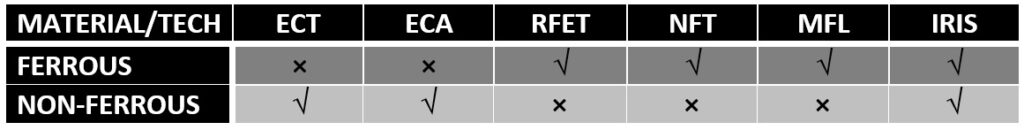

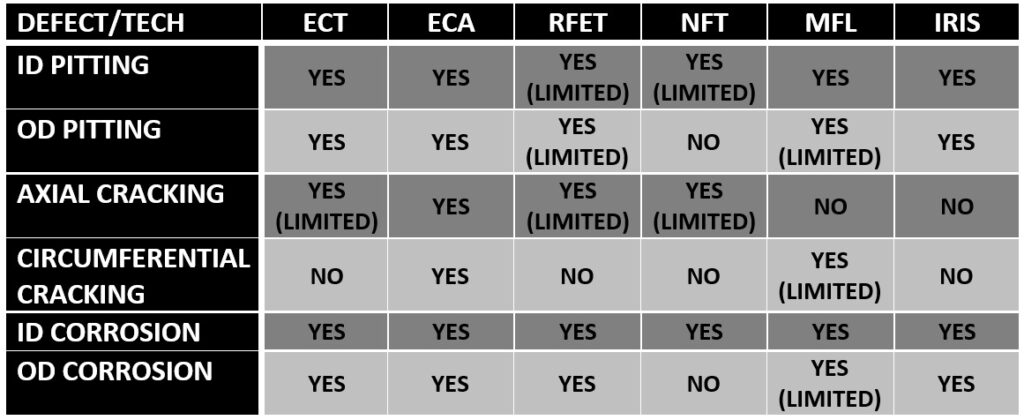

Tube inspection techniques include Eddy Current Testing, Eddy Current Array Testing, Remote Field Eddy Current Testing, Near Field Testing, Magnetic Flux Leakage and IRIS.