Visual Inspection, also known as Visual Testing (VT), is the oldest, most versatile, and most commonly used non-destructive test (NDT) method. Used alone or in conjunction with other test methods, qualified visual inspection is a reliable and highly cost effective tool for quality control. It is simple, easy to apply, quickly carried out and usually low in cost. The basic principle used in visual inspection is to illuminate the test specimen with light and examine the specimen with the eye. In many instances aids are used to assist in the examination. Visual inspection can be used for internal and external surface inspection of a variety of equipment types, including storage tanks, pressure vessels, piping, and other equipment

Visual inspection is sometimes carried out in conjunction with the following devices

- Magnifying Glass- Generally consists of a single lens for lower power magnification and double or multiple lenses for higher magnification.

- Magnifying Mirror- This one is a concave reflective surface, such as a dental mirror may be used to view restricted areas

- Microscope- It is a multiple element magnifier, providing very high power magnification, is used for the inspection of parts removed from the aircraft. Some portable units are also used to evaluate suspected indications found on the aircraft.

- Borescope- Borescope is a precision optical instrument with built-in illumination. Borescopes sometimes called ‘endoscopes’ or ‘endoprobes’, which consists with superior optical systems and high intensity light sources, some borescopes provides magnification option, zoom controls or accessories.

- Flexible Fibre Optic Borescope- Permits manipulation of the instrument around cameras and through passages with several directional changes.

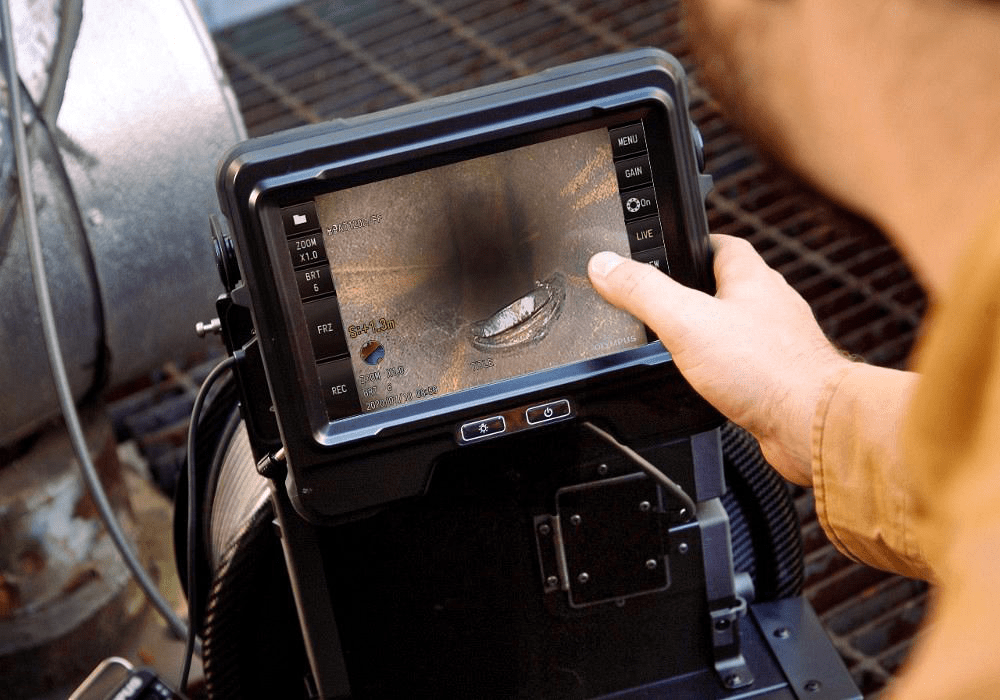

- Video Imagescope- The video Imagescope is similar to a Fibrescope with the exception that video camera and its connections have replaced the image bundle and a TV monitor has replaced the eyepiece. This image may be magnified for precise viewing.